Price 130000.0 आईएनआर/ Unit

Specification

- एलॉय

- Aluminium

- साइज

- Standard

- शर्त

- New

- मोटाई

- मिलीमीटर (mm)

- रंग

- Grey

Trade Information

- Minimum Order Quantity

- 10 Units

- भुगतान की शर्तें

- , ,

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य निर्यात बाजार

- , ,

- मुख्य घरेलू बाज़ार

About

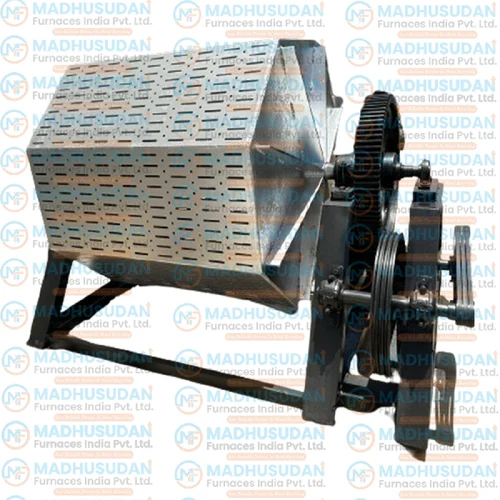

A Dross Ball Mill Machine is a specialized type of industrial milling machine used to grind aluminum dross a by-product of aluminum smelting into a fine powder. The main objective is to recover aluminum from the dross more effectively.

What is Aluminum Dross?

Aluminum dross is a mixture of aluminum metal and aluminum oxide formed on the surface of molten aluminum during melting, casting, or recycling. It contains recoverable metallic aluminum that can be extracted with the right processing.

Dross Ball Mill Machine Overview

| Feature | Description |

|---|---|

| Purpose | Grinding aluminum dross to recover fine aluminum particles |

| Type | Rotating cylindrical drum filled with grinding media (steel or ceramic balls) |

| Process | Impact and attrition between balls and dross material reduce particle size |

| Material Input | cold aluminum dross |

| Output | Fine powder with separated metallic aluminum and oxides |

| Automation | Can be manual, semi-automatic, or fully automatic |

| Cooling | airflow for cooling hot dross |

How It Works

-

Loading: Aluminum dross is fed into the machine.

-

Grinding: Balls inside the rotating drum break the dross into smaller particles.

-

Separation: Aluminum metal is separated from oxide residues using sieves, classifiers, or additional refining steps.

-

Collection: Fine aluminum particles are collected for recycling; oxides can be used for other industrial purposes.

Advantages

-

Increases aluminum recovery

-

Reduces waste disposal cost

-

Compact and efficient

-

Environmentally friendly (less landfill dross)

Safety & Maintenance

-

Operate with proper PPE (dust can be hazardous)

-

Regular inspection of liners, bearings, and grinding media

-

Control temperature if processing hot dross to prevent combustion

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें